What Is 5s In The Workplace

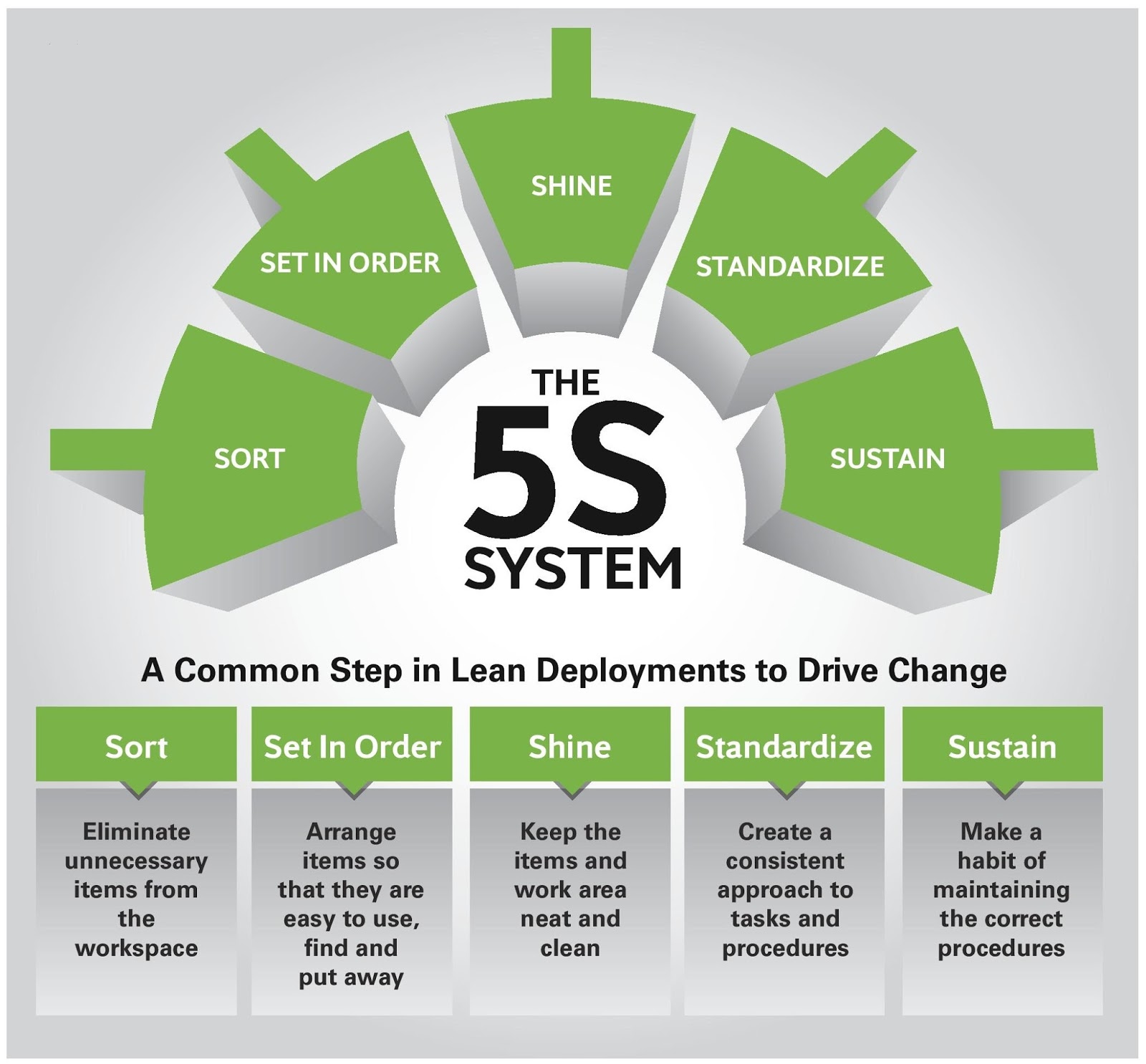

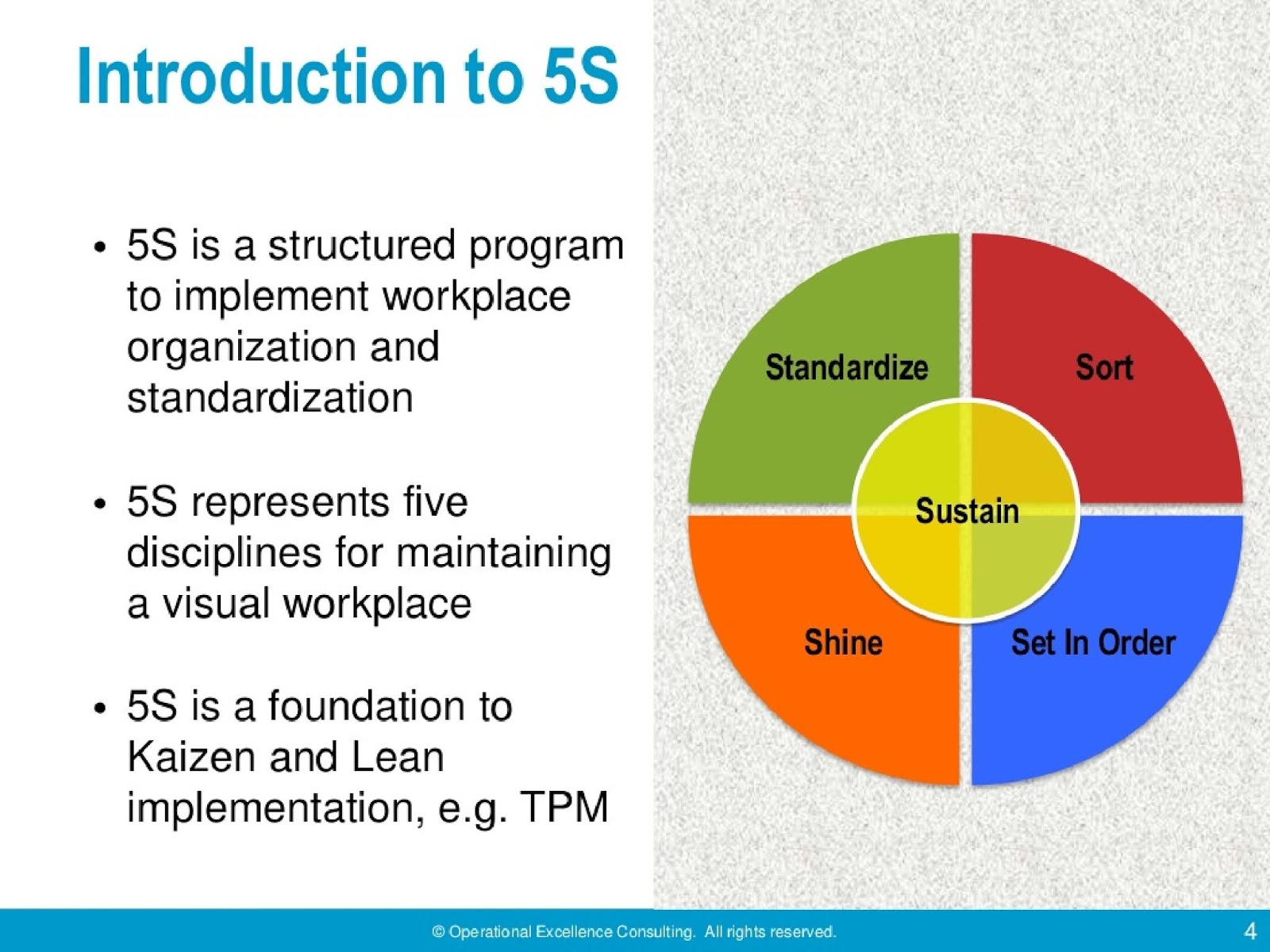

What Is 5s In The Workplace - 5S is a systematic way of organizing workplaces by eliminating waste improving flow and reducing the number of processes where possible It applies the five principles Sort seiri Set in order seiton Shine seiso Standardize seiketsu and Sustain shitsuke The 5S System is an effective methodical process for reducing waste and making your workplace more efficient and organized There are five steps Sort Set in Order Shiny Clean or Systematic Cleaning Standardized Cleanup and Sustain It s important to move through the system in sequence

What Is 5s In The Workplace

What Is 5s In The Workplace

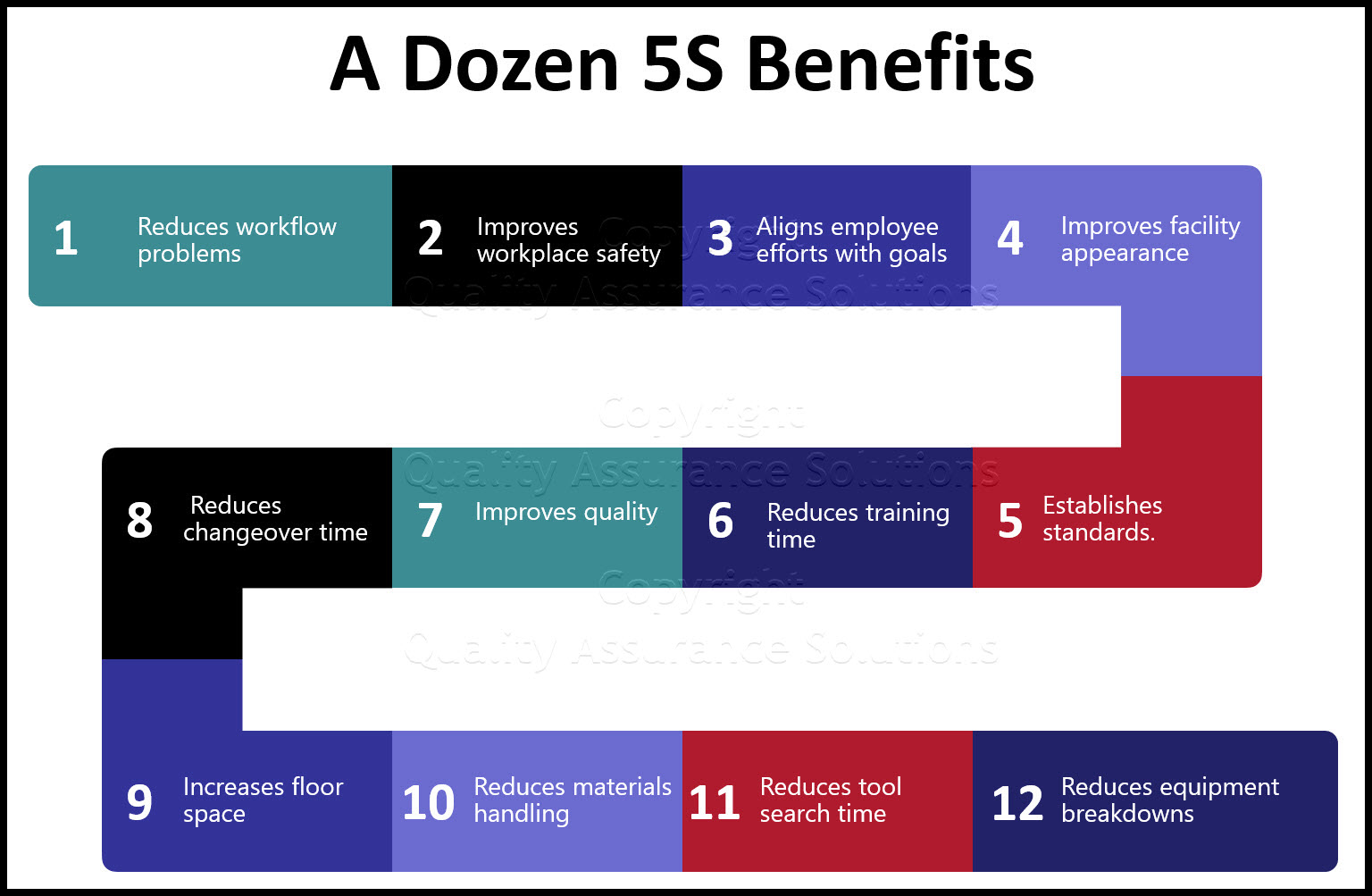

In the long run, though, 5S makes processes run more smoothly and prevents mishaps, and those things usually save businesses money. Boost efficiency, safety & quality with 5S! Learn how this Lean system improves workspaces, reduces waste, & engages employees. Get started today! 5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. [1]

The 5S System Reducing Waste And Increasing Productivity Mind Tools

Lean Workplace 5S Poster PST829

What Is 5s In The WorkplaceUpdated 27 August 2023. Most companies use the 5S system to maintain proper organisation within the work environment while ensuring it's efficient, clean and safe. With the 5S system, companies can build businesses with continuous improvement through discipline, reducing waste and achieving substantially better results with fewer resources. 5 Principles of 5s Sort Seiri All items equipment and work materials should be neatly arranged and all unnecessary objects should be Set in Order Seiton All items equipment and work materials should be in optimal locations The objective is to Shine Seiso The workspace including

The 5S methodology is a powerful tool for improving workplace organization, efficiency, and safety. By following the five steps of the 5S method – sort, organize, clean, standardize, and sustain – organizations can create a more productive and enjoyable work environment. File 5S Methodology png 5S Workplace Organization YouTube

5S methodology Wikipedia

HSE Insider The 5S System

The true purpose of 5S goes deeper than a one-time housecleaning. The 5S methodology is a way to: create standards that reveal problems, support the basic stability needed to sustain incremental gains, reduce waste in all forms, build a disciplined workplace where teams focus on value -creating work, and nurture the essential sense of shared . Lean Manufacturing Concepts 5S System A Place For Everything Safe

The true purpose of 5S goes deeper than a one-time housecleaning. The 5S methodology is a way to: create standards that reveal problems, support the basic stability needed to sustain incremental gains, reduce waste in all forms, build a disciplined workplace where teams focus on value -creating work, and nurture the essential sense of shared . The 5S Process 7 Visualizations That Explain It Best Document Management A 5S Opportunity Continuous Improvement Blog

Ph ng Ph p 5S Vi t Quality

5S Workplace Organization What Is 5S And Its Benefits

This 5S Poster From CSS Was Designed With Lean On The Mi

5S System Promoting Workplace Quality And Safety

Bad 5S In The Office AllAboutLean

5S Visual Management

What Is 5s Methodology 5S Quality System 5S Workplace Management

Lean Manufacturing Concepts 5S System A Place For Everything Safe

5S Lean 5S Principles In The Workplace SafetyCulture

5S The Basics Of Workplace Organization Better MRO